A strategic relocation marks another step in our journey towards commercial deployment

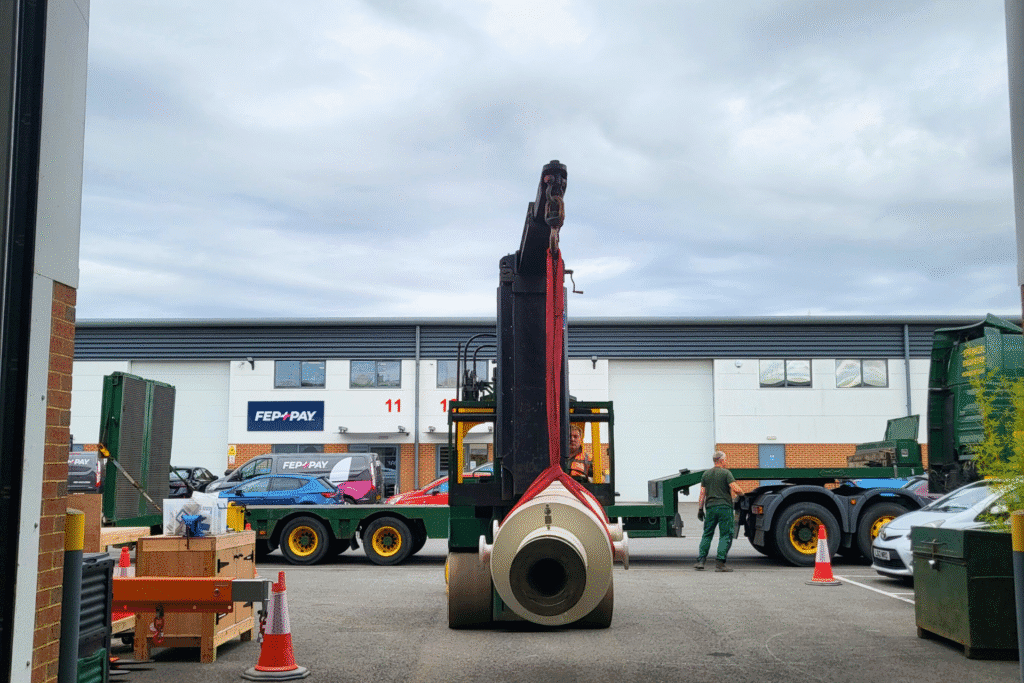

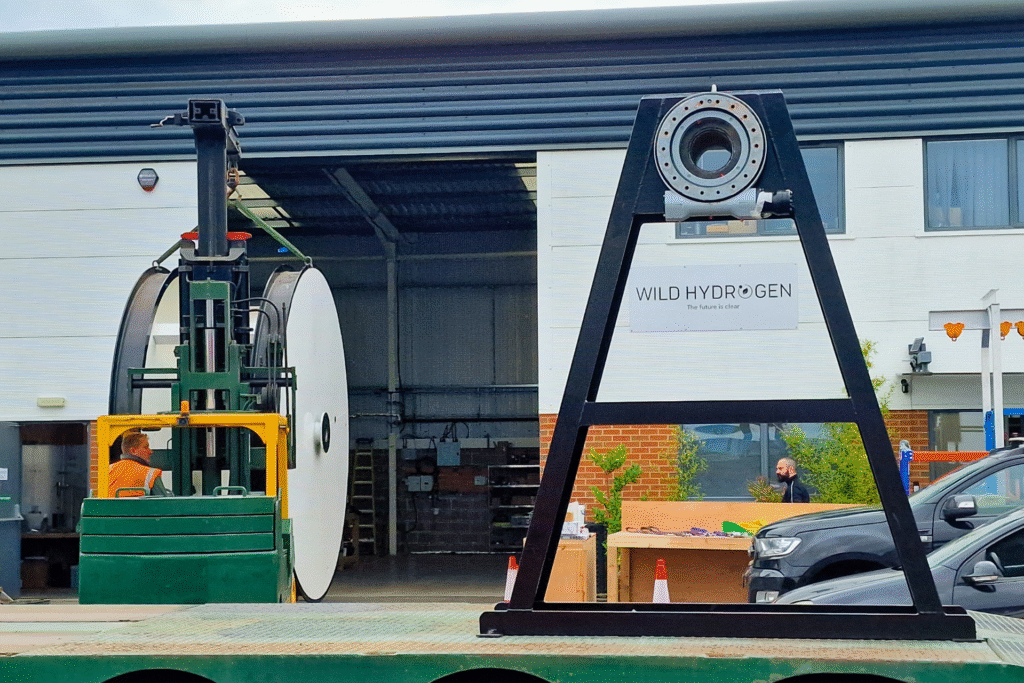

Yesterday marked a significant milestone in Wild Hydrogen’s growth trajectory as we successfully relocated our TRL 6 prototype “Mini” from our headquarters workshop in Gloucester to our sister site at Meadow Mill. This move represents far more than a simple change of location – it’s a strategic step that positions us for accelerated development and commercial readiness.

Why This Move Matters

The relocation of Mini serves two critical purposes that align with our aggressive scale-up timeline:

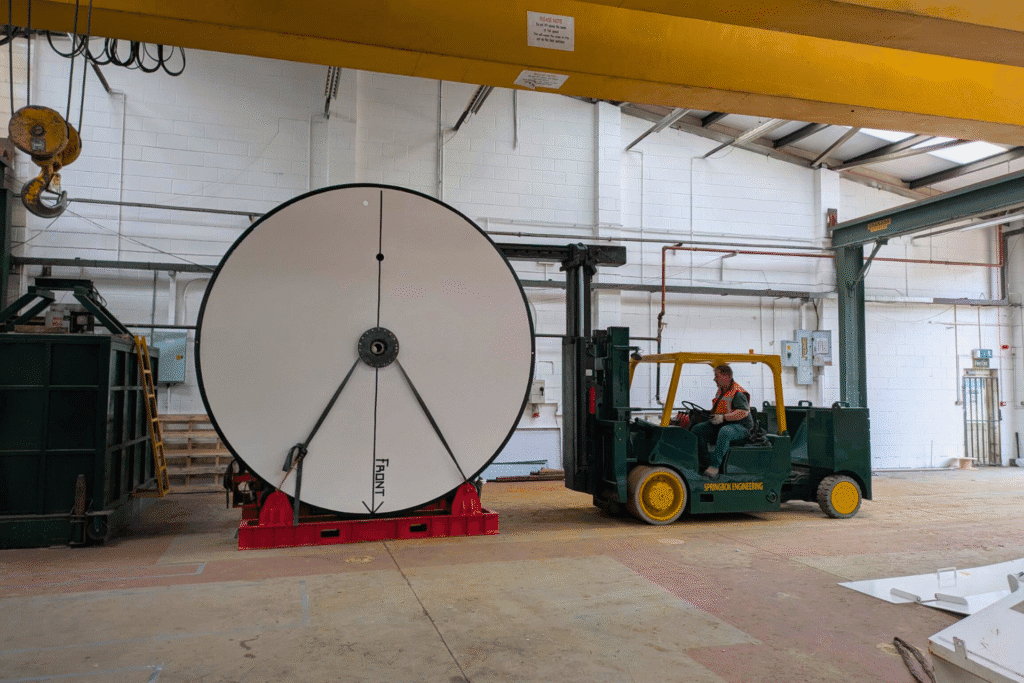

Clearing the way for progress: Our HQ workshop has been the birthplace of four successful Rising Pressure Reformer prototypes, from our initial proof-of-concept “Millie” through to Mini itself. However, as we prepare to build additional reactors and advance our technology development, workshop space has become precious real estate. Moving Mini creates the essential capacity we need to continue our rapid prototyping and testing cycles.

Real-world testing environment: Meadow Mill isn’t just a storage facility – it’s the designated site for our future commercial demonstrator plant. By positioning Mini at this location, we’re creating a dedicated test bed where we can validate the sub-systems and operational procedures that will be critical for our commercial demonstrator. This hands-on approach allows us to identify and resolve potential challenges in the actual environment where our technology will operate at scale.

From Laboratory to Industrial Reality

Moving from our laboratory workshop to an industrial site represents more than just logistics – it’s a clear demonstration of our progression towards commercial deployment. Mini, our largest prototype to date, has already proved the scalability of our supercritical water reforming technology. Now, in its new operational environment, Mini will play a crucial role in de-risking our scale-up process as we advance towards TRL-8.

The prototype will serve as our testing ground for validating critical sub-systems, operational protocols, and maintenance procedures that will inform the design and construction of our commercial demonstrator. This practical, iterative approach ensures that when we begin construction of our full-scale plant, we’ll have thoroughly tested and optimised every component.

Looking Ahead

This relocation aligns with our broader development timeline as we work towards launching our commercial demonstrator in 2028. With Mini now positioned at Meadow Mill, we can accelerate both our technology development at headquarters and our operational validation at the commercial site.

The move also reflects the growing momentum behind Wild Hydrogen’s mission. With industrial partnerships already secured with SUEZ and Wales & West Utilities, and funding from Innovate UK supporting our technology development, we’re building the foundation for widespread deployment of our Rising Pressure Reformer technology across Europe.

As we continue to prove that any organic waste can be converted into clean hydrogen and biomethane as well as valuable biochar, each milestone brings us closer to realising our vision of a circular economy where waste becomes a valuable energy resource.

Moving forward with our vision of a fossil fuel-free future, one prototype at a time.